Optimizing Supply Chains: The Power of Campaign Planning

Read how the Campaign Planner & Designer (CPD) helps you to manage supply chain variability.

The digital transformation of supply chains is underway, and many initial successes have been achieved. However, existing digital technology is far from being applied at scale, and significant value is still up for grabs for supply chain managers. Beyond implementing new data lakes and AI technology, companies need to take an end-to-end approach and systematically rethink their processes, operating model, roles, skillsets, as well as the IT and data target landscape to capture the full potential of digital supply chains.

The last five to ten years have seen bustling activity in the digitization of supply chains across all sectors, triggered by a series of breakthroughs on multiple levels. The innovation in foundational technologies (like massive parallel computing and the availability of affordable hyper-scale cloud platforms) has boosted machine learning and analytics, leading to remarkable breakthroughs like those of DeepMind AlphaZero in 2017 [1]. Step by step, real-time and data-driven optimization has then been integrated into planning and ERP systems and enabled companies to use digital twins of their networks or supply chains to simulate and optimize complex supply chain strategies. And we are just witnessing the start of the revolution. In 2019 alone, AI companies attracted nearly $40 billion globally in disclosed investment, led by the US, China, and Israel[2].

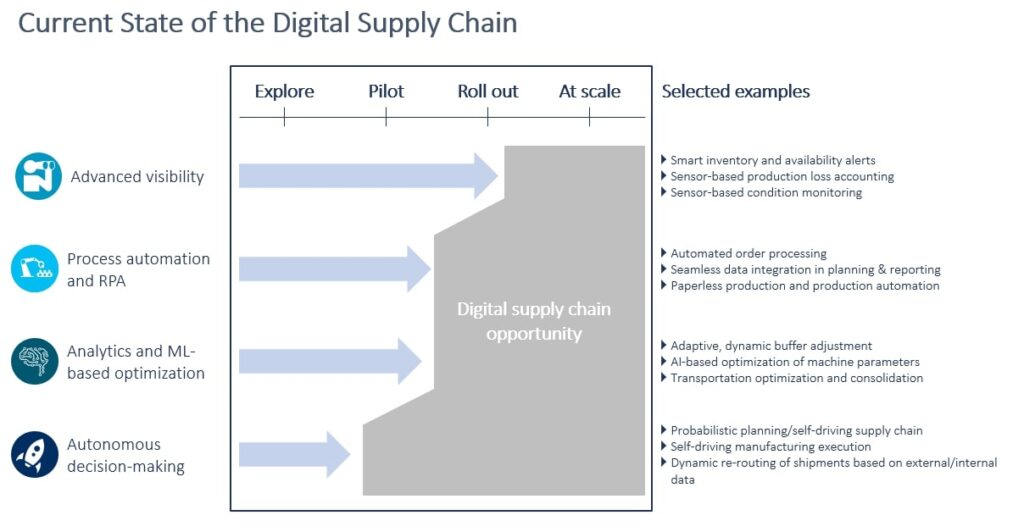

Digital supply chain innovation has come out of the starting blocks in the last five years and helped companies drive improvements in four key areas:

At first, we saw many digital applications in supply chain visibility, e.g., real-time dashboards for operational performance down to plant and production line level and new workflows for management enabling fast and data-driven decision-making. On top of visibility, companies have used process automation and RPA extensively to transform transactional supply chain processes such as customer order management and operational procurement.

But that was only the first step. Now smart automation embeds AI algorithms in RPA and allows the partial automation of decision-making processes such as exception management, allocation, and even S&OP (RPA 2.0/hyperautomation)[3].

In parallel, companies have been working on deeply integrating analytics and machine learning into core supply chain processes and decision-making. Examples include forecasting, and nowadays end-to-end parametrization, intelligent alerts, and automated analytical root cause analysis of issues, e.g., backorders and delays.

These advances already point to the final area, autonomous decision-making, and the self-driving supply chain. With probabilistic planning and impact simulation in digital network twins, machines can increasingly handle tactical and operational trade-off decisions, strike a balance between alternative options in an automated way, and only raise alerts to the supply chain planners in case of exceptions and ambiguities.

Overall, the digital supply chain is out of the starting blocks, with lots of exciting ventures and achievements to show for it. However, we have captured only a fraction of the value potential, with lots of opportunities still to be harnessed, e.g., by extending existing approaches and moving to next-generation supervised autonomous decision-making.

In the next section, we will outline the impact that the digital supply chain will have on the supply chain operating model.

As we have experienced in a broad range of digital supply chain projects across industries, digital has proven to drive value in optimizing physical processes, such as manufacturing and logistics, and has improved information flows in data management, end-to-end supply chain planning, strategic sourcing, and operational procurement. Figure 2 gives an overview of the key application areas and use cases.

It is important to note that these are not just some independent use cases. Instead, digital and analytics are transforming the core operating model of supply chains step by step, resulting in five central paradigm changes:

What is your approach to digitizing your supply chain? Let us know your thoughts and feedback!

[1] “AlphaZero: Shedding new light on chess, shogi, and Go”, David Silver et. Al, December 6, 2018, https://deepmind.com/blog/article/alphazero-shedding-new-light-grand-games-chess-shogi-and-go (visited February 11, 2021)

[2] “What investment trends reveal about the global AI landscape”, Zachary Arnold, September 29, 2020, https://www.brookings.edu/techstream/what-investment-trends-reveal-about-the-global-ai-landscape/ (visited February 11, 2021)

[3] “Robotic process automation i: A path of hyperautomation”, Henrik Baumeier et. Al, January 15, 2021, https://blog.camelot-group.com/2021/01/robotic-process-automation-i-a-path-of-hyperautomation/ (visited February 11, 2021)

We would like to thank Sebastian Hild for his valuable contribution to this article.

Read how the Campaign Planner & Designer (CPD) helps you to manage supply chain variability.

Explore automated production planning with our Campaign Planner & Designer.

The pharma market trends impact logistics with a shift to smaller, higher-value shipments and new temperature requirements.

This blog post explores the role of remanufacturing and outlines how it can be successfully integrated into Product Lifecycle Management.

© Camelot Management Consultants, Part of Accenture