AI-Driven Application & Process Testing: Embracing Agentic Testing

Learn how Agentic AI enables digital transformation, delivering true hyperautomation.

As we are in the middle of a sustainability revolution, the pressure is on manufacturing operations. As a major user of energy and natural resources, as well as origin of major waste streams, manufacturing operations need to integrate sustainability deeply into their production systems and decision-making from shopfloor to network level. Smart digital solutions are the critical enabler for this step change.

In the last year, we have seen an increased focus on a sustainability transformation in line with the Paris agreement, not only from politics, but also from international finance, customers both B2B and B2C, and manufacturing companies themselves. With the need to go zero-carbon until 2035 to 2045, we are in the middle of an industrial transformation of historical dimensions.

And industrial manufacturing is in the middle of this transformation. Global manufacturing is still the biggest single carbon emissions source, ahead of energy production and agriculture. This is due to the large amount of electricity, gas, oil, or steam to produce our steel, cement, plastics, cars, smartphones, or furniture. Overall, the contribution of manufacturing operations is estimated at 15 bn tons of CO2, or 30% of the 50 bn tons global emissions (see Oxford University 2022)

For example, global emissions from manufacturing are 50% higher than the footprint of China (Oxford University 2022, China). Counter to common intuition, manufacturing emissions are not falling, but have largely outpaced the growth of other sources since 1990, driven by a large increase of demand. On top of CO2 emissions, manufacturing is also responsible for the generation of large quantities of waste and wastewater, toxins, pollution, and the consumption of many resources.

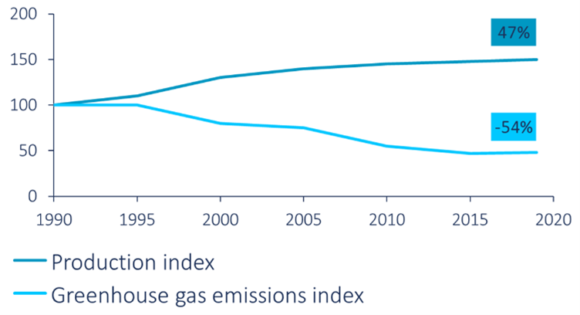

Manufacturing is the central place for further optimization and minimization of emissions and overall natural resource consumption. Technology and process improvement can be fruitful, as proven by the decoupling of emissions and production in the European chemicals sector (Fig 1).

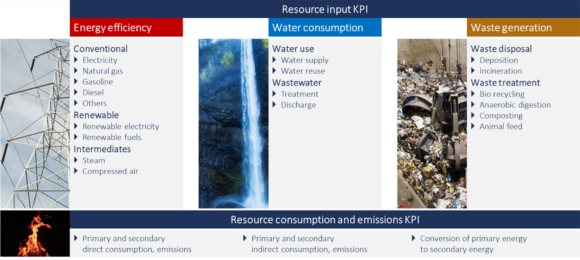

However, the manufacturing sector needs to further accelerate efforts to minimize resource consumption across the three areas energy efficiency, reduced consumption of water, or reduction of disposed or incinerated waste (Fig 2).

Manufacturing operations’ huge opportunity to minimize natural resource consumption is in practice contrasted by what we call the operationalization gap: while many companies have a clear sustainability strategy and roadmap, the concrete footprint of energy, water, waste, and emissions is still not sufficiently transparent on the shopfloor, where decisions are taken every day. Manufacturing teams are often struggling to adequately measure and then manage the sustainability impact of day-to-day operations. This issue can be observed in different forms in many companies, for example when

In summary, creating transparency on sustainability metrics and embedding sustainability as a core dimension of success in production systems is a major challenge for manufacturing companies of all sizes.

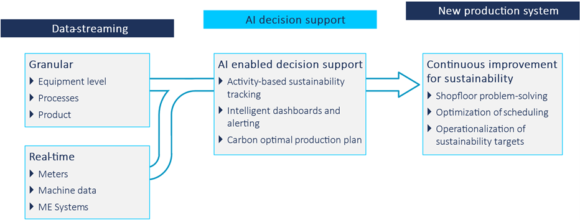

How to make this major transformation in manufacturing happen? Based on our work with manufacturing clients, we have identified three key principles which are critical prerequisites for the sustainability revolution in manufacturing (Fig 3). Above all, companies need to take a holistic approach which involves people skills and an operating model, as well as the right set up for digitalization to make this happen.

First, companies need to make data accessible for optimizing the sustainability impact of daily operations. On the one hand, this means a granular data collection via sensors on equipment level. These data streams must be allocated to activities along the process to connect products with resource use and emissions. On the other hand, data need to be collected, transformed, and analyzed in real-time using streaming technology, so that they can be used for actual shopfloor decision-making.

Secondly, companies need to focus on decision support, instead of sustainability reporting. AI decision support technology can be used to effectively transform masses of streaming data depending on the purpose, providing shopfloor decision makers with precious alerts, root cause analyses, and recommendations for action. Take for example alerting on energy peaks or prioritizing top root-causes of energy consumption as input for a problem-solving session on a production line.

Thirdly, the new sustainability focus needs to be embedded in the production system. This means including sustainability in work routines and performance management. Only if natural resource consumption has a clear place in operator routines, shift handovers, performance reviews, problem-solving sessions, and management discussions, will positive change hit the road. The operationalization gap between high level targets, “carbon neutral by 2050” for example, and tangible change on the shopfloor can finally be closed.

All this can only be achieved when treating digitally enabled sustainable manufacturing not as an IT project, but as a close cross-functional collaboration of operations management, site leadership, shift teams and operators, engineering & maintenance, operational excellence, and IT.

What would AI-enabled decision-making for sustainable manufacturing look like concretely?

The first step is to install and connect a hierarchy of meters and assign them to production assets, e.g., gate meters between production units or areas and on equipment. Then, data streams from the meters-hierarchy are transformed in real-time by machine learning services into readable data and allocated to processes and products.

Data and insights are streamed in real-time to targeted dashboards on the shopfloor and leveraged by operators, shift-leaders, and engineering to optimize production processes, e.g., minimizing natural gas usage or water consumption. Insights on peaks or deviations are used in problem solving sessions on the shopfloor, to continuously improve sustainability performance.

The hierarchical setup enables that the same data can be aggregated on higher levels, e.g., energy use per output unit for all plants producing a certain product range in the network. Based on that information, central operations strategy, operational excellence, and sustainability teams can continuously understand sustainability performance, identify best practices in the network, and accelerate the path to climate neutrality based on data and AI supported decisions.

With increasing wealth of data on sustainability on plant, production area, equipment, and product level, the team uses AI services to support decisions for optimization of production scheduling, standard work, and routines. Decisions on sustainability performance improvement can now be taken on products (i.e., decommissioning of a certain product line because of its unduly high footprint) as opposed to the usual discussion on plant level (i.e., high energy consumption in a plant, but unclarity on improvement path because of broad product range).

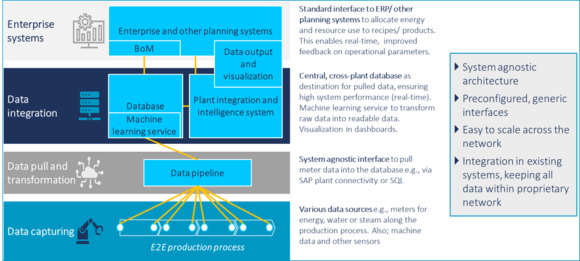

To support this new world of sustainable manufacturing, companies need to find the right technological set up. This set up would typically consist of a four-layer architecture (Fig 4) starting with a “data capturing layer”, where multitudes of different data sources and protocols can be combined, e.g., machine/ equipment data, additional meters, and sensors such as temperature, flow, optics, etc. The “data pull & transformation layer” acts as a system-agnostic data-pipeline to transform and provide data in real-time to various analytics applications. These are supported by the “data integration layer”, which includes a database and machine learning service to provide readable data for dashboards for value-generating analytics. A connection to enterprise systems is critical not only as input for data transformation (e.g., providing bill of materials or production schedules to allocate energy use to products), but also to receive data output, e.g., to include sustainability information in ERP reports and planning tables.

Key principles for such a digital manufacturing infrastructure are a system-agnostic design and a lean database. To allow for efficient and fast scaling of the approach across the network, it is also recommended to use the provided, generic interfaces to connect to other manufacturing intelligence systems, as this allows to further leverage insights. Above all, the technology set up needs to allow for gradual and agile proof of value, configuration, and deployments of new metrics, dashboards, and sustainability routines in more and more sites in the network.

The zero-carbon transformation of manufacturing operations is quickly becoming a license to operate for companies and is a top management priority. CEOs and COOs need to support the change not only by allocating sufficient resources and investments, but especially by re-focusing management on a holistic manufacturing management approach which goes beyond quality, agility, and cost, but deeply integrates the sustainability element into management decision-making.

Below are five strategic questions which can help surface the need for action and trigger necessary discussions to move forward:

Reach out to the Camelot team for sustainable manufacturing if you want to learn more.

Learn how Agentic AI enables digital transformation, delivering true hyperautomation.

Reimagine resilience and proactively minimize supply chain risks

This article shall help you to understand how to optimize your inventory positions in a month – or even less.

Modern PLM systems empower businesses to achieve product excellence in fast-paced markets by enhancing collaboration, agility and innovation.