AI-Driven Application & Process Testing: Embracing Agentic Testing

Learn how Agentic AI enables digital transformation, delivering true hyperautomation.

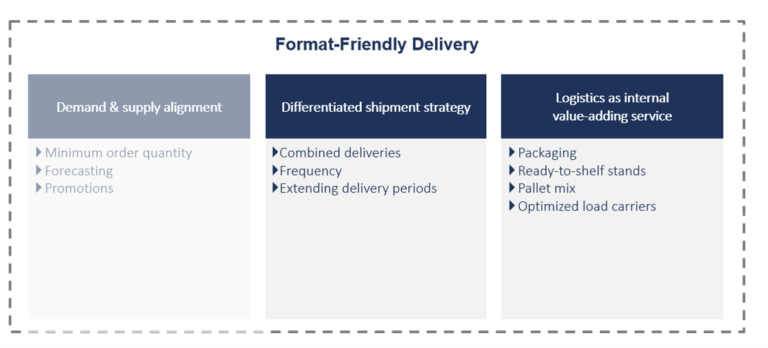

A format-friendly delivery is the starting point for shaping the future grocery retail supply chain. Introducing on-demand deliveries and value-adding services in the supply chain can help to boost sales performance.

In our previous article, we have discussed format-friendly delivery as a key principle of shaping successful supply chains in grocery retail. We have shared our thoughts on aligning demand and supply for the different sales channels through adapting minimum order quantity, using advanced forecasting, and introducing new ways to manage promotions. This article will round up the starting point towards an end-to-end supply chain strategy in grocery retail with differentiated shipment strategy and logistics as an internal value adding service.

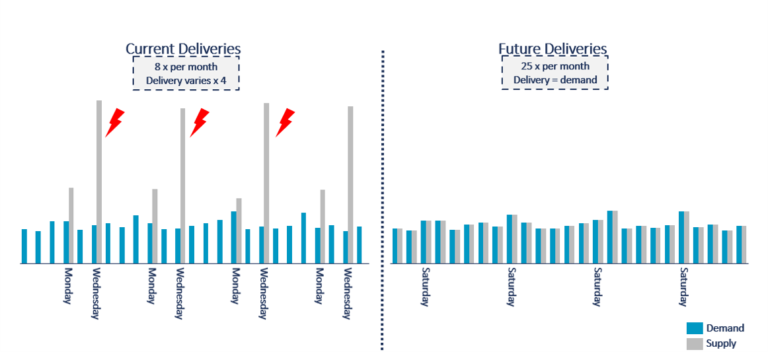

It is common industry practice to delivery super fresh SKU such as fish or daily prepared meals on a very frequent basis. It is not unusual that supermarkets get delivered multiple times throughout a single day ensuring high freshness. Dry or frozen SKU on the other hand, typically get delivered less frequently. Especially convenience stores with lower demand receive less delivery attention.

On the left side of exhibit 2 an exemplary demand and supply pattern for dry goods for a convenience store is shown. The store gets delivered twice a week on Monday and Wednesday.

From our perspective, the delivery patterns need to be changed to better match demand.

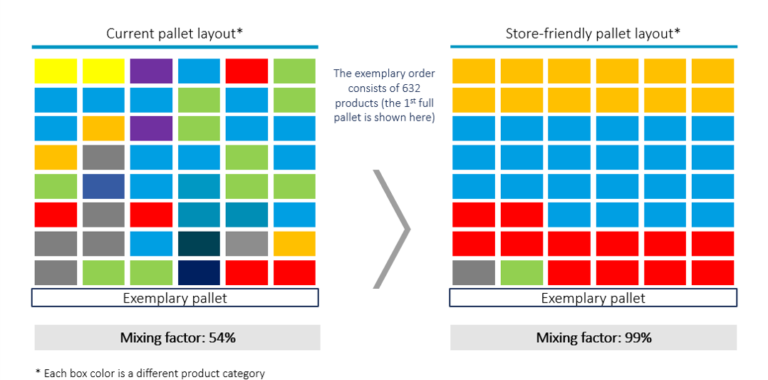

Apart from the before mentioned design choices, we see two further options to enhance store performance. In this case, supply chain ready packaging and store-friendly palletizing both improve in-store replenishment efficiency.

In summary, a differentiated shipment strategy with combined deliveries and extended delivery periods helps to reduce stock out and improves in-stores operations efficiency. Logistics as internal value-adding services using supply chain ready packaging and SKU positioning in the warehouse further improves in-store operations performance.

This post is the fourth part of our blog series on how to build a future-proof grocery retail supply chain. Further parts of the series:

Part 1: How to Shape Your Future Supply Chain – Omnichannel in Full-Assortment Grocery Retail

Part 2: The Three Principles of Future-Proof Grocery Retail Supply Chains

Part 3: Grocery Retail: How to Align the Supply Chain towards Market Demands

Part 5: Setting the Table: Designing a Supply Chain Network in Grocery Retail

Learn how Agentic AI enables digital transformation, delivering true hyperautomation.

Reimagine resilience and proactively minimize supply chain risks

This article shall help you to understand how to optimize your inventory positions in a month – or even less.

Modern PLM systems empower businesses to achieve product excellence in fast-paced markets by enhancing collaboration, agility and innovation.

© Camelot Management Consultants, Part of Accenture

Camelot Management Consultants is the brand name through which the member firms Camelot Management Consultants GmbH, Camelot ITLab GmbH and their local subsidiaries operate and deliver their services.