AI-Driven Application & Process Testing: Embracing Agentic Testing

Learn how Agentic AI enables digital transformation, delivering true hyperautomation.

A leading biopharmaceutical company met the pressing demand for lifesaving COVID-19 vaccines, demonstrating their agility. Now, the move from a global pandemic to an endemic condition provides their next challenge. How can supply chain processes be transformed from a crisis-driven planning model to one that fosters stability and continuity?

During the pandemic, the urgency of vaccine production necessitated rapid adjustments and a one-size-fits-all approach. Despite the unprecedented challenges, the organization achieved remarkable success in delivering vaccines to a world in need. Today, people around the globe reclaim a sense of normalcy, shedding their masks, as infection rates become more predictable and stable. With the shift to endemic status, the corporation recognized the imperative of transforming its supply chain processes. Key considerations included adapting to country-specific product requirements, ensuring long-term sustainability, and navigating evolving regulatory landscapes. In response to these challenges, Camelot partnered with the company to initiate a comprehensive restructuring effort.

Camelot collaborated closely with the company’s dynamic supply chain team, leadership, and strategic partners to support a transformative journey aimed at elevating the network-wide planning process to new heights of reliability and efficiency. This endeavor encountered challenges in two key areas: processes and systems.

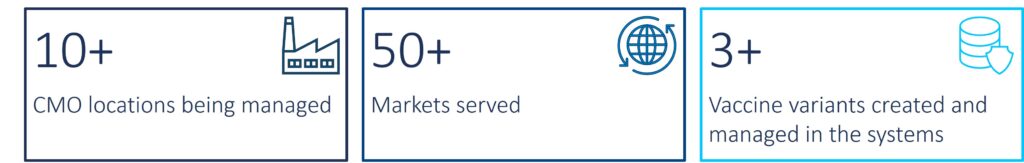

Establishing robust processes: The supply planning process underwent a significant transformation including the development of integrated global coordination with Contract Manufacturing Organizations (CMOs). The previous push planning model, established during the height of the pandemic with several regional variations, evolved into a globally orchestrated planning process with strengthened cross-functional communication. This transformation integrated key processes like Sales and Operations Planning (S&OP) and Sales and Operations Execution (S&OE) to navigate seasonal COVID-19 vaccine production challenges with confidence. After the expiry of a pandemic emergency authorization, country-specific stock-keeping units had to be introduced, increasing the complexity of internal and CMO operations. Prolonged governmental decisions on vaccine variants in combination with long lead times also required a refined mater data concept and governance. This comprehensive transformation aimed to unify and streamline global operations, ensuring supply chain resilience amidst ongoing uncertainty and change.

Implementing a next-level planning system: A transition away from the previously decentralized Excel-based planning approach marked a significant milestone in this project. This shift embraced a unified data approach, effectively managing the substantial volumes of data involved. This transformation was a critical enabler for a more resilient and data-driven supply chain management system.

The supply planning process redesign enabled the transition from pandemic to endemic operations. Moreover, it paved the way for the company’s sustained growth, offering stability after an exceptional period of global development. This transformation exemplifies the ability to address complex supply chain challenges and achieve remarkable results in the face of evolving circumstances.

The swift implementation of supply planning processes and tools proved to be a pivotal strategy for the company’s supply chain as the COVID season drew near. These forward-looking initiatives have played a vital role in effectively tackling the distinctive challenges posed by COVID-19 vaccine seasonality. Mishandling these challenges could result in production delays, jeopardizing the ability to meet the peak demand.

The success achieved in this endeavor sets the stage for a promising future. The establishment of a single source of truth coupled with improved planning has significantly reduced scrap and enhanced the ability to respond well to demand fluctuations. These enhancements align seamlessly with the demands of an endemic landscape, fortifying the supply chain’s adaptability and resilience.

Furthermore, the pharmaceutical-specific benefits, such as refined shelf-life control and visibility in the S&OP and S&OE processes, alongside the transformation towards a harmonized, globally coordinated planning organization, distinguish the company’s supply chain achievements in the industry. Anticipating the introduction of new products, the processes are well-prepared for further diversification and sustained growth.

Learn how Agentic AI enables digital transformation, delivering true hyperautomation.

Reimagine resilience and proactively minimize supply chain risks

This article shall help you to understand how to optimize your inventory positions in a month – or even less.

Modern PLM systems empower businesses to achieve product excellence in fast-paced markets by enhancing collaboration, agility and innovation.

© Camelot Management Consultants, Part of Accenture

Camelot Management Consultants is the brand name through which the member firms Camelot Management Consultants GmbH, Camelot ITLab GmbH and their local subsidiaries operate and deliver their services.