Risk & Resilience in Logistics Network Design

Reimagine resilience and proactively minimize supply chain risks

Circular economy describes the trend towards business models that shift the usage of resources from the currently predominant take-make-waste system to a sustainable system where resources and materials are circulated, sustained, and regenerated. Social, environmental, and economic drivers are accelerating the shift towards a circular economy and require companies to fundamentally change their value chains to close the loop. We outline the five circular loops as the core principles of the circular economy and how companies can pivot their business models based on them to become circular. Each company must envision their own individual role in circular economy depending on their unique value chain position and capabilities to find their specific sweet spot in the upcoming transition to a green future and sustainable economy.

Today’s economy is mainly linear. The Circular Gap Report estimates that the status of global circularity is at 8,6% in the year 2020 as shown at the center of Figure 1. But there is a potential to double circularity to reach 17% by implementing a set of different measures. This does not seem like a lot but is estimated to cut total global emissions by 39%. The transition towards the circular economy is driven by social, ecological, and economic drivers for sustainability, which unfold in five dimensions that reinforce each other.

Consumers are becoming increasingly aware of sustainability topics and understand that sustainability is more than greenhouse gas emissions. The circular economy addresses pressing concerns of consumers like ocean plastic, resource waste in fast fashion, deforestation, lack of recycling, and prevention of waste. It expands and compliments the common sole focus on carbon emission towards a more holistic view on sustainability.

This also translates into reducing the environmental impact. About 45% of global greenhouse gas emissions are caused by product manufacturing and utilization of land and can be addressed by applying circular economy principles. The Circular Gap Report, a global cross-sector initiative with stakeholders from academia, businesses, NGOs and governments, estimates that if we reach the potential circularity of 17% and additionally implement the Nationally Determined Contributions set down in the Paris Agreement, we can cut enough greenhouse gas emissions to stay below the 2°C climate goal. Moreover, especially the EU understands that closed loops help to preserve valuable resources in the economy and reduce dependency on commodity volatility as well as external supply, especially from socially and environmentally questionable sources.

Therefore, the goals of climate protection and resource preservation as well as the consumer demand leads to more and more regulations, which support the transition to circular economy. Especially in Europe, we see many upcoming regulations including the Circular Economy Action Plan, upcoming non-recycled plastic taxation, the EU Green Deal, OECD plastic waste shipping bans, and many more. These regulations incentivize and promote the transition to a circular economy and discourage or even simply restrict contrary business activities.

All the above-mentioned factors cause the finance sector to include sustainability and ESG criteria into their investment strategies. Low performance of a company in terms of sustainability becomes a financial liability. Non sustainable business models, like fossil-based energy production, might be at risk in market environments with high focus on sustainability and thus might have no viable perspective in the future. Investors refrain from investing in these companies. Low performers might simply have problems funding their business operations in the future. Moreover, the market for sustainable investments and green bonds is booming.

Last but not least, the circular economy evokes huge business potentials. According to estimations, circular business models could have a market potential of up to 4,5 Trillion US-$. As a leader in the circular economy, companies can combine environmental and economic success to gain a clear competitive advantage and increase their profitability. In the next section, we want to explore the possibilities and nature of those circular business models.

The circular economy offers solutions to combine economic and ecological sustainability by fundamentally changing the way we make, use, and dispose of products and goods. Instead of the take-make-waste behavior in the traditional linear economy, resources and materials are circulated, sustained, and regenerated. To become a leader and seize the full potential of an upcoming sustainable, closed-loop economy, companies must pro-actively envision their future role. Business models and value creation in a circular economy are based on a set of foundational principles: the circular loops. However, there is no one-size-fits-all solution. Each company must envision their own role with individual circular business models depending on their unique value chain position and capabilities to find their specific sweet spot. Based on our experience, companies must follow key elements:

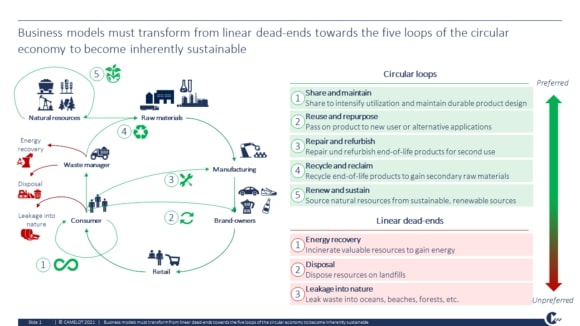

In this new circular economy, value add is generated in business activities building on circular loops. We can identify five general closed loops across industries to create value and preserve resources. On the other side, there are three linear dead-ends, which are legacies of the past, expiring linear economy and waste valuable resources.

The first loop, share and maintain describes the intensified utilization of products by sharing them and extending the product lifetime significantly via durability and maintaining. Extending the product lifetime and making the product accessible to be used by a larger amount of consumers are very effective measures to satisfy a larger demand with the same amount of resources. Companies can translate this principle into profitable activities by applying share or “as-a-service” models. The customer pays for the product use and the company obtains re-occurring fees for providing and maintaining the product. Car sharing to increase the utilization or renting schemes for equipment are illustrative examples for building upon share and maintain schemes.

The reuse and re-purpose as well as repair and refurbish circular loops both describe principles to extend the lifetime and usage of a product by returning them to a manufacturer or brand owner to be prepared for another use cycle. In the reuse and re-purpose scheme, products are returned and either reused for the same purpose (e.g., after cleaning) or they are repurposed to be used for an alternative application. In the repair and refurbish scheme, products need a more extensive treatment after being returned. The products needs to be repaired, broken parts might need to be exchanged with spares, or the product is modified to be used in another application. Second hand cloth are an commonly known example for the reuse and re-purpose loop. Repair and refurbish schemes are for example prominent in buying refurbished consumer electronics and are currently also explored in the remanufacturing of lithium-ion batteries for electrical vehicles.

The recycle and reclaim is one of two ways to obtain raw materials in a sustainable and circular way. The loop describes the recovery of resources from end-of-life products. End-of-life products are collected and treated in order to gain secondary raw materials and recyclate, which can be used in the production of new products. To recycle plastic, metals, glass, and paper are common applications of the recycle and reclaim scheme. Also urban mining falls in the category of an extensive recycling and reclaim scheme from aggregated and concentrated resources in urban areas.

Last but not least, renew and sustain is the second way to obtain raw materials in a sustainable and circular way. Raw materials are sourced and grown from renewable and regrowing natural resources instead of relying on fossil or other finite resources. In addition, strict social and environmental criteria need to be applied to secure the regeneration of a natural resource, like sustainable forestry and land use. If a resource is finite by nature, like minerals or ores, the mining process should at least protect the social and ecological environment by guaranteeing health, safety and human rights as well as minimizing the impact on natural habitat and restoring it after exploration.

The linear dead-ends are a legacy of the linear economy and are avoided in a circular economy due to the loss of precious resources and the loss of value. Energy recovery describes the incineration of end-of-life products. Though end-of-life products are burned to obtain energy for heating or electricity, the materials in the products are lost forever instead of being used as valuable resources, as secondary raw materials. Disposal describes the dumping of end-of-life products in landfills. Leakage into nature is by far the worst way of handling end-of-life products, since waste is simply dumped, intentionally or unintentionally, into the environment and poses a thread to the environment and health.

In general, circular loops and linear dead-ends follow a logic from preferred to least preferred, depending on their degree of resource and value conservation. This is indicated in Figure 2 by the scale on the right. The most preferred preserve the value and material of a product the most and vice versa. Although organizations should pay attention to the logic, it really depends on the characteristics of the product and value chain which circular loops fit best and can be translated into a successful and sustainable circular business model.

Each company can build their circular business models and created sustainable value based on the circular loops explained above. For each industry and product, the five potential circular loops need to be adapted and used to derive a fitting circular solution to match the unique and individual characteristics of the respective market. Due to the inherent characteristics and given nature of different products, markets, or utilization, some circular loops are more useful than others in a specific industry or business. There is no one-size-fits-all solution. To succeed, companies need to take following criteria into consideration:

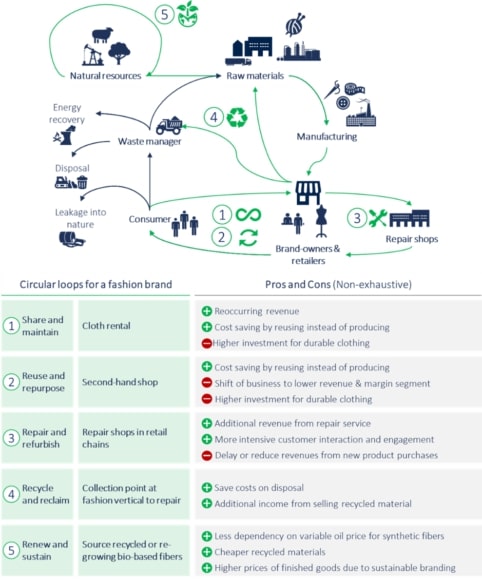

In this way, circular business models open new ways of profitability. Although they might substitute existing business models from the linear economy, they should ideally create new potential for profits, either via new revenue streams or simply via cost savings. Figure 3 shows illustrative potential business models based on the circular loops for the clothing or fashion industry and potential pros and cons for each. Each of the circular loops is applicable to the fashion industry and business models can be build around them.

After identifying potential business models, companies must envision their own role with individual and detailed out circular business models depending on their unique value chain position and capabilities, and assets to find their specific sweet spot. To stay with the example of the fashion industry: Not only the fashion brands, but also other players like manufacturer or retailer in the fashion industry must decide which of the circular loops and corresponding circular business models are worth considering from their individual situation.

For example:

This is a great example to show that loops can be operated individually or combined in many cases.

We have shown that circularity is not only driven by pressure of consumers and politics to become sustainable, but that it is also required by the finance sector, as well as to harvest new business potential. The concept of circular economy allows companies and organizations to combine economic success with social and environmental sustainability goals. To become a leader and seize the full potential of an upcoming sustainable, closed-loop economy, companies must pro-actively envision their future role. Business models and value creation in a circular economy are based on a set of foundational principles, the circular loops. However, there is no one-size-fits-all solution. Each company must envision their own role with individual circular business models based on their unique value chain position and capabilities to find their specific sweet spot.

Read our further articles on this topic:

We share the picture of the five loops and the three linear dead-ends:

Reimagine resilience and proactively minimize supply chain risks

This article shall help you to understand how to optimize your inventory positions in a month – or even less.

Modern PLM systems empower businesses to achieve product excellence in fast-paced markets by enhancing collaboration, agility and innovation.

Read how the Campaign Planner & Designer (CPD) helps you to manage supply chain variability.

© Camelot Management Consultants, Part of Accenture

Camelot Management Consultants is the brand name through which the member firms Camelot Management Consultants GmbH, Camelot ITLab GmbH and their local subsidiaries operate and deliver their services.