AI-Driven Application & Process Testing: Embracing Agentic Testing

Learn how Agentic AI enables digital transformation, delivering true hyperautomation.

Allocation planning is a complex subject with no definitive solution. However, there are key best practices that, if followed, lead to satisfactory outcomes. This article will illustrate a standard allocation planning model, highlight best practices, and outline a customized ‘allocation redistribution’ approach, including allocation reservation for key customers and consideration of sales orders.

Today, supply chain disruptions are commonplace, posing constant challenges that every supply chain must address. As end-consumers demand increasing visibility and commitments from B2C companies, B2B enterprises must provide higher levels of transparency to maintain customer service levels (CSL) and avoid penalties.

The COVID-19 pandemic has significantly impacted the world’s supply chains. Now that the proverbial toothpaste is out of the tube, businesses must react swiftly to maintain their competitive advantage. One notable change of recent years is the increased expectation and monitoring of order promise dates for accurate, on-time deliveries. More supplier contracts now include delivery and fulfillment penalties for failing to meet set order promise dates and quantities. Supply chain disruptions are inevitable. Furthermore, trying to manage a spreadsheet that is passed around for review is time-consuming and leads to planning inaccuracies.

A competitive advantage can be gained if customers can trust accurate order promise dates and quantities regardless of supply bottlenecks. Even if the promised amount falls short of the request because of disruptions, on-time and in-full deliveries of promised quantities foster trust between customers and suppliers. Allocation planning can efficiently manage inventory in both bottleneck and non-bottleneck situations and is increasingly recognized as a best practice for maintaining CSLs during supply chain bottlenecks.

In a traditional allocation model, customers are allocated a portion of the available supply based on specific criteria, typically their order history over a period, such as the last six months. A more robust approach considers historical sales alongside a predetermined forecast horizon to generate allocation quantities. There are inherent risks to mitigate whether using sales history, forecast, or both together. Utilizing an appropriate statistical forecasting method is crucial, alongside demand history that has been cleansed of causal outliers such as sales promotions and event outliers such as supply bottlenecks. An additional benefit of this customer-centric approach is that product distributions across locations will naturally evolve and pair to existing and future customer demand; avoiding some of the inventory imbalances that can occur through traditional supply distribution methods. Other than a determined time period (e.g., monthly) and a planning granularity (e.g., location, product, customer), an optimal product allocation model requires three key components:

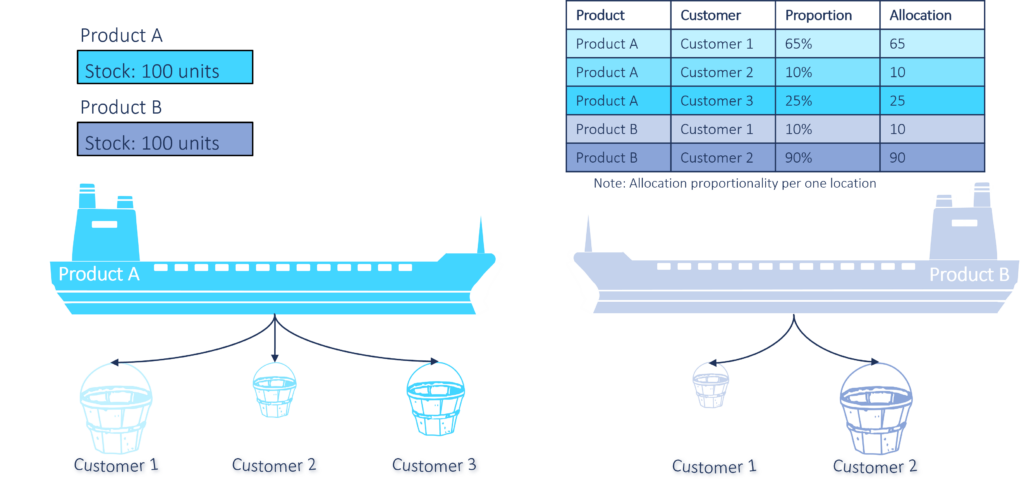

Imagine product allocation as customer ‘buckets’ — not your standard buckets, but dynamically sized to precisely match the proportion of each customer’s product demand over the evaluation period (Figure 1). Each customer is assigned an appropriately sized allocation bucket, representing the maximum amount they can order given supply constraints in the current period. The order in which these buckets are filled is determined from a priority list that considers contractual agreements and business priorities. Within each priority segment, the method of inventory distribution could vary, involving either demand sequencing or a fair-share distribution method.

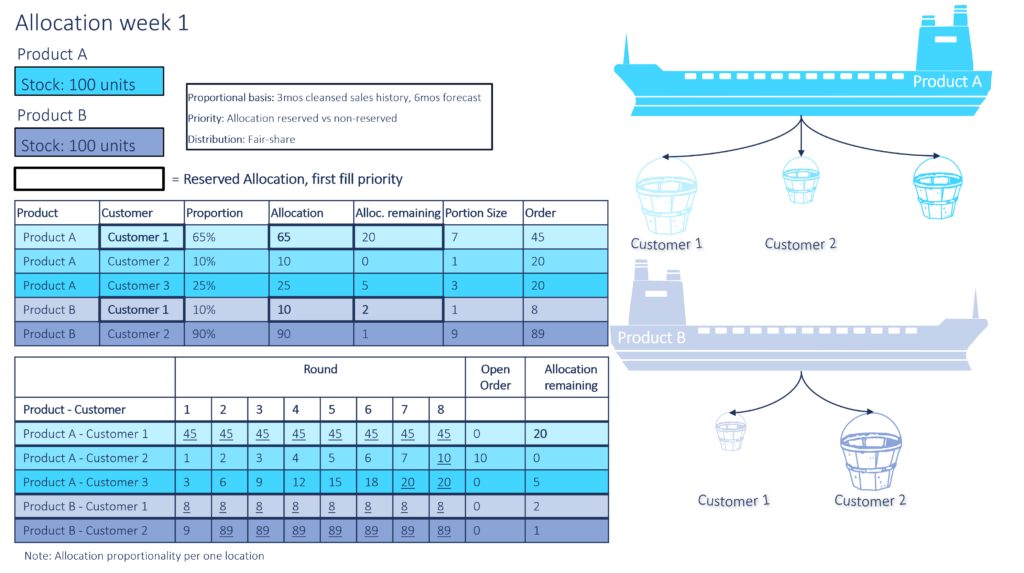

Figure 2 illustrates a fair-share scenario showcasing allocation distribution based on available demand inputs and resources. Key observations include:

While generally effective, this model may prove inadequate for many organizations. Reserving inventory for non-ordering customers, especially in short-supply situations (i.e., supply bottlenecks), presents challenges in meeting other customer demands.

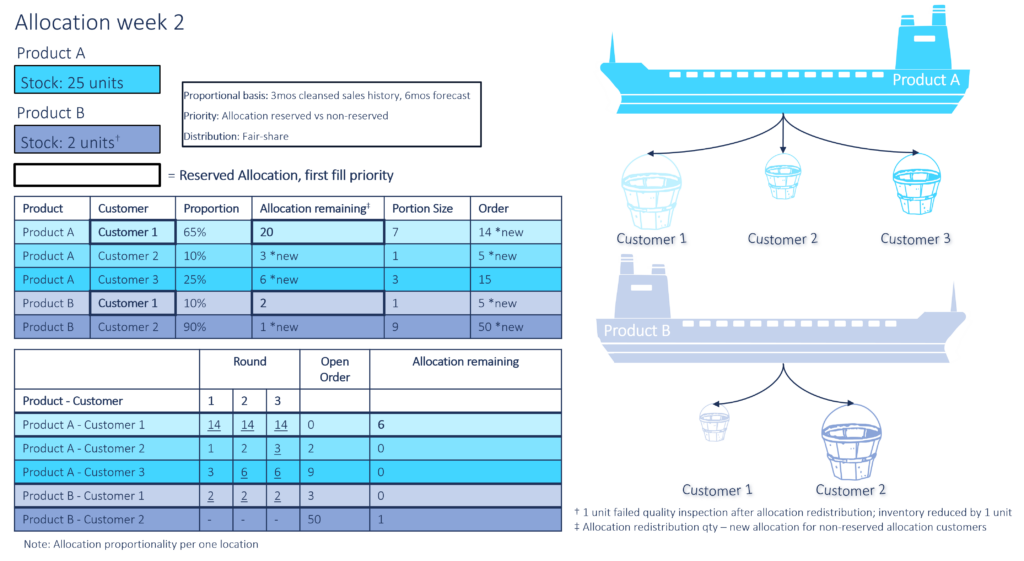

Standardized methods to meet business requirements are lacking where allocation is available to non-ordering customers but not to those with open sales orders. Standard allocation models often oversimplify, neglecting the necessity to include multiple diverse inputs. Integrating sales orders into the allocation process could enhance the system, allowing customers with open sales orders to receive extra allocation when supply permits (Figure 3). Addressing this business need in a recent client project involved developing a system and process that utilizes multiple demand inputs, planning versions, and a weekly allocation generation cadence.

At the beginning of each month, allocation is generated by proportionally disaggregating the demand forecast. Subsequently, a combination of planning filters and demand inputs are employed to ensure static customer allocation quantities are maintained and dynamic allocation is generated to distribute any available inventory to open sales orders.

In this ‘allocation redistribution’ approach, four demand inputs are considered:

1. Reserved allocation values are a demand input for customers with fixed allocation needs

2. For customers without static allocation requirements, their consumed allocation is copied to maintain a minimum allocation commensurate with their allocation consumption

3. Next, open sales orders are assessed

4. Finally, the remaining open forecast quantity is calculated by deducting open sales orders from the current open forecast value

The sum of these four inputs mentioned above determines the new allocation quantity. Allocation consumption accumulates monthly, enabling appropriate allocation redistribution each week. This customized allocation method is highly flexible, allowing various demand inputs for allocation generation. In a world of inevitable supply disruptions, proper procedures are crucial for meeting CSL requirements. This customizable approach ensures the necessary flexibility to fulfill business requirements while upholding order promise dates and quantities.

Learn how Agentic AI enables digital transformation, delivering true hyperautomation.

Reimagine resilience and proactively minimize supply chain risks

This article shall help you to understand how to optimize your inventory positions in a month – or even less.

Modern PLM systems empower businesses to achieve product excellence in fast-paced markets by enhancing collaboration, agility and innovation.