AI-Driven Application & Process Testing: Embracing Agentic Testing

Learn how Agentic AI enables digital transformation, delivering true hyperautomation.

In times of high uncertainty, advanced tools and methods are needed to build a resilient supply chain. By identifying vulnerabilities and moving to probabilistic planning, uncertainties can be better addressed. Among the various tools and methods gaining prominence, scenario planning is a valuable option for addressing these uncertainties. In the following, we present its use for more agile end-to-end supply chain planning in order to gain a competitive advantage.

Over the past year, challenges of the VUCA (Volatility, Uncertainty, Complexity, Ambiguity) world became more visible than ever. The Covid-19 pandemic had a significant impact on different industries, at times quite diverse. While various companies had to put their operations to a halt, online retailers experienced historically high demands. More than one year after the outbreak, it is still uncertain what impact the pandemic will have in the long term. Additionally, other ecological, economic, political, and social developments are increasing uncertainty in supply chain management.

Some driving factors of this uncertainty are external and cannot be influenced. When governments are better controlling the virus’ spread in their territory, in turn, it brings more confidence to consumers. Businesses might also be granted additional governmental support to avoid severe impact. As we have seen, the different elements are in constant interplay and influence each other. For example, shutdowns and business restrictions can depress businesses and discourage end customers. At the same time, limited supply can harm producers that are willing to ramp up production.

In general, the challenges companies are facing can be summarized as follows:

As a result, it is not possible to precisely plan production, purchasing and transportation. Therefore, an approach is needed to manage the different alternatives.

We strongly believe that it is important to manage risks and exploit potential to gain a sustainable competitive advantage. We’ve only lately learned how difficult it is to react to uncertainty when pandemic strikes. Also, businesses’ capacity to plan for foreseeable delays connected to the pandemic’s future path is currently limited. Since reacting to disruption alone does not improve supply chain resilience, a more proactive approach is needed.

Furthermore, the current crisis has identified an apparent lack of consideration of uncertainty, siloed optimization, and missing end-to-end visibility in supply chain planning. In order to handle these lacks, you either can 1) address a strategic horizon by reconsidering the structure of the supply chain, the portfolio and customer market strategy regarding more resilience, or 2) take actions within the current supply chain structure addressing the tactical and operational horizon.

In any case, many businesses will benefit from a detailed action plan that is thought through and ready to be implemented proactively. Here, scenario planning is highly beneficial: It forecasts probable realities based on the challenges in a given situation.

This article discusses tools and actions to be taken on the tactical and operational level (see Figure 1).

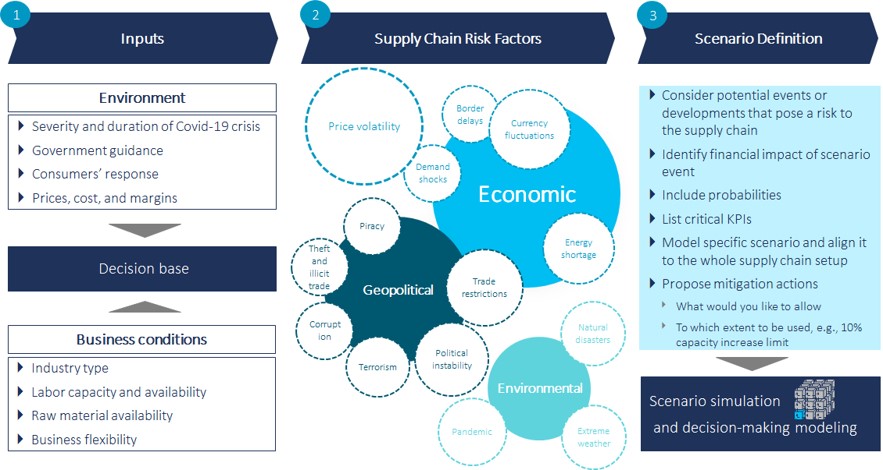

In general, scenario planning involves three major steps. It starts with consideration of the environmental and business conditions as necessary inputs for the decision base. The next step is to determine supply chain risk factors that exist in the current environment. After that, findings are used for the scenario derivation and evaluation.

As we are already able to estimate the impact of the recent events onto our business by evaluating consequences, we must start thinking about actions to avoid them. Here, it is crucial to

This involves the evaluation of risks and opportunities and a close investigation on critical KPIs and short-term goals (e.g., shortening lead times).

Scenario planning entails making assumptions about the future and how the market climate will evolve based on those assumptions. Scenario planning, to put it another way, identifies a particular collection of uncertainties or various “realities” of what may happen in your company’s future. It is crucial to monitor and evaluate the potential events and their financial and non-financial impacts. This includes and is not limited to losing key employees or brand recognition, threatens business continuity, resulting in lost markets, too high investments, and scenarios not coming up.

With scenario planning, we are not simply estimating a forecast which can be then highly accurate or completely wrong. We consider various sets of different futures, identify what might happen within your supply chain, and calculate probabilities. And there can be thousands of different scenarios that include various factors, such as lead times, demand changes, shipping costs, service level, etc. It is vital to have a list of critical KPIs that different planners and C-level decision-makers define. Their dependencies and requirements are essential to consider defining the room for maneuver.

Based on this, action plans are prepared including specific mitigation actions. The executive or leadership team must agree on what they are be willing to allow – for example, would they permit any additional capacity that covers demand recovery. The action plan clearly explains what type of mitigation measure it includes and to what extent it can be used. Because several business units are involved in this activity, the S&OP planning process is ideal for analyzing various situations and coordinating planned activities across all organizational roles.

In general, we suggest the following steps (see Figure 2).

As an underlying approach, select the most appropriate planning system to meet the constantly changing needs. Ideally, it must cover cross-functional roles such as demand planning, supply planning, sales, marketing, production, and logistics.

If that is done, closely observe the market conditions, configure different scenarios you’re your own business, and run simulations to quantify and evaluate the potential impact.

Next, one should implement risk management techniques and focus on resilience against the pandemic. Supply chain resilience refers to both the ability to identify supply chain vulnerability and thus the ability to reduce supply chain risk in a focused way. Traditional supply chain risk management tries to identify and prepare for numerous external risk events instead of focusing on what can be controlled and predicted in the end-to-end supply chain.

Defining the KPIs as key checkmarks is the next logical step. As mentioned above, the list of KPIs defined by planners provides advanced insight into which of these scenarios is actually playing out. Overall, the scenario planning raises awareness of the activities that will shape the organization’s future and how to deal with them.

As for the supply chain risk management in practice, one must consider the necessary changes to minimize the adverse effect. Next, one should test the impact of these changes on the operations with the help of simulations within scenario planning. Each scenario is simulated as if it were taking place in real life. In this case, the planner examines how a particular decision (e.g., capacity expansion) looks like in each scenario.

A comprehensive data set or digital twin is the basis for good scenario planning. It should reflect the actual supply chain as closely as possible. Since it consumes a lot of time to map the supply chain with its numerous factors and complexity in Excel spreadsheets, send them back and forth by e-mail, and constantly update them, we advise advanced supply chain planning tools, e.g., SAP IBP. As most of such advanced tools, it includes comprehensive supply chain data and real-time supply chain planning synchronization. This makes it a handy tool to support scenario planning. Possible future events and actions can be easily mapped into simulations. These can be saved, shared, and compared in scenarios or versions. Here, saved ad-hoc simulations in which individual changes can be quickly modeled and shared are called scenarios – they serve as decision support. On the other hand, complete data sets are copied into versions, where individual master data can also be modified – they serve as a basis for monthly planning.

The derivation of supply scenarios out of demand scenarios helps to evaluate and proactively manage risk. Apart from that, the implications of these scenarios on resources can be controlled. More specifically, the portion of demand covered, capacity impact, and inventory impact can be evaluated in terms of turnover, costs, and potential lost revenue. Finally, decisions can be made about inventory allocation, hiring, maintenance, shift patterns, or capacity expansion. This ability to visualize different scenarios and their impact on various relevant factors, from supply planning to financial perspectives, promotes unbiased cross-functional decision-making at each planning level. It finally leads to a more structured discussion on the relevant supply chain parameters. Firefighting activities can be mitigated, and supply chain planning becomes more flexible and resilient.

The Covid-19 pandemic has mainly triggered immediate actions to be taken to respond to sudden changes or shortages. Since the way forward is still not clear, strategic activities are primarily short-term, and firms are in a wait-and-see mode. However, business leaders must consider various possible outcomes and plan their potential actions to overcome harsh consequences.

Supply chain resilience should be a top priority in general and especially so in the current crisis times. When planning for the recovery phase—or a potential secondary crisis—a scenario-driven approach is the best. It allows supply chain leaders to boost supply resilience and gain transparency across the value chain. Moreover, it helps leaders to understand the coronavirus’s risks as well as its opportunities. Having a clear vision and a list of various scenarios and associated risk mitigation responses brings deeper visibility, faster decision-making, and more confidence to your business in these uncertain times.

We would like to thank Juliette Budner for her valuable contribution to this article.

Learn how Agentic AI enables digital transformation, delivering true hyperautomation.

Reimagine resilience and proactively minimize supply chain risks

This article shall help you to understand how to optimize your inventory positions in a month – or even less.

Modern PLM systems empower businesses to achieve product excellence in fast-paced markets by enhancing collaboration, agility and innovation.

© Camelot Management Consultants, Part of Accenture

Camelot Management Consultants is the brand name through which the member firms Camelot Management Consultants GmbH, Camelot ITLab GmbH and their local subsidiaries operate and deliver their services.