Risk & Resilience in Logistics Network Design

Reimagine resilience and proactively minimize supply chain risks

Managing value chains has become a difficult task – especially since COVID-19 hit economies globally. Organizations will only persist if their value chains are future-proof. In this blog post we introduce six key drivers for value chain excellence.

Value chain challenges have increased heavily over the past years. A rising cost pressure for leaner inventories and a demand for shorter lead times are forcing supply chain processes to accelerate. At the same time, a higher product complexity and product variety requires more flexibility and adaptability. Also, the new standard for supply chain networks is global sourcing, production, and demand. This is reflected in the global trade development over the past 15 years: Before COVID-19, the total global export value was already 80% higher compared to 2005 according to WTO [1].

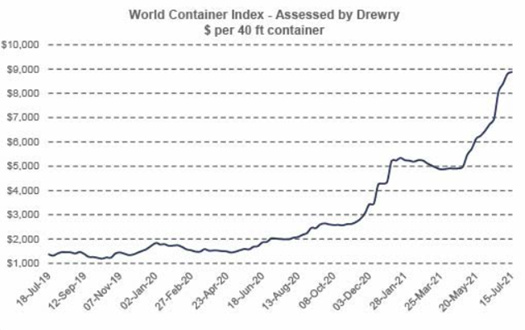

Managing value chains becomes even more difficult in times of ongoing challenges. To point out just one key figure: The average cost of shipping for a full container have skyrocketed to almost $9,000 mid of 2021 – which is more than six times the price compared to two years before.

This has enormous implications on short-term to mid-term sourcing profitability as well as strategic sourcing and supply chain network design decisions.

We expect the market environment to become even more competitive than before, and we will continue to live in a world of disruptions. Therefore, it is important to make your value chains future proof and turn them into a competitive advantage. Key to success is focusing on the processes as the core of any value chain as we will show in the next section.

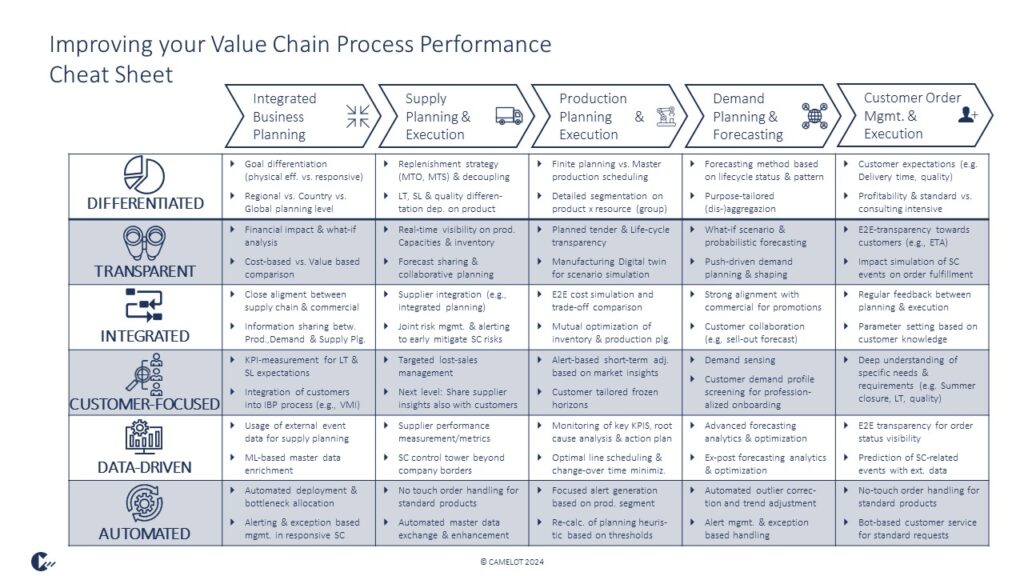

Smoothly running integrated processes are at the core of any high-performing value chain. The main value chain processes can be summarized in five process areas:

It is vital to keep these core processes competitive, sustainable, and well-functioning to manage value chains in safe waters.

But what does well-functioning exactly mean? There are six characteristics that drive excellent value chain processes:

Combining these six characteristics helps to create value chains that can compete in today’s economic environments and are ready for the future.

The six drivers for value chain excellence can be applied where they provide the highest benefit to one of the five processes along the value chain, from integrated business planning to customer order management and execution. In the following section we will show what we consider as exemplary main performance drivers for the five process blocks.

For integrated business planning, a forward-looking transparency and the integration of demand, supply and financials are key. Through financial impact analyses, profitability implications of supply chain decisions and events should be made transparent. The supply chain can be prepared for demand or supply shocks beyond usual oscillations by data-driven what-if analyses. Also important is the close integration of production as well as demand and supply planning, with clearly defined communication and feedback loops, transparent targets and mutual KPIs.

The supply planning and execution process needs to be tailored for instance to the targeted replenishment strategy, i.e., MTO or MTS. Different strategies require different processes and decisions for specific products, e.g., placing of supply chain decoupling points. Key suppliers need to be integrated into the value chain of a company to enable collaborative planning and joint risk management to mitigate supply chain disruptions in early stages.

For the production planning and execution function, a manufacturing digital twin will help to optimize production processes, create transparency, and simulate stress tests for creating resilience. End-to-end automation of processes by robotics and optimization algorithms reduces manual errors, lowers the risk exposure for workers and achieves precise and reliable production results. With close coordination and integration of production and tactical planning by closed feedback loops, inventories will be optimally managed and expected lead times fulfilled.

With demand sensing, real-time data can be used to create more accurate forecasts by incorporating current market realities [3]. This enables you to better tailor forecasts to actual customer demands. Advanced forecasting analytics allows to automatically select time-series profiles, choose best fitting forecast models, and enrich the resulting forecasts.

A high level of automation in the fulfillment of customer orders often shows itself in a large no-touch order rate for standard products, or a bot-based customer service for standard requests. High transparency can be achieved by regularly updating and communicating the ETA (expected time of arrival) towards the customer.

How long the to-do list for your value chain excellence project is, depends – of course – on your starting point, the maturity of your competition, and the goals you want to achieve. If you want to turn your value chain into a competitive advantage, the transformation of your value chain needs to start as soon as possible.

As a general rule, we recommend focusing on the key value chain processes, understand what you want to improve, and identify the performance drivers you need!

Feel free to connect with us on LinkedIn to get for more insights on the individual processes in our upcoming LinkedIn posts!

[1] WTO stats: International Trade statistics: https://stats.wto.org/

[2] AJOT: American Journal of transportation: https://ajot.com/news/drewry-world-container-index-15-jul

[3] Byrne, Robert F. (Summer 2012). “Beyond Traditional Time-Series: Using Demand Sensing to Improve Forecasts in Volatile Times”. Journal of Business Forecasting. 31 (2): 13–19.

We would like to thank Florian Kreitz for his valuable contribution to this article.

Reimagine resilience and proactively minimize supply chain risks

This article shall help you to understand how to optimize your inventory positions in a month – or even less.

Modern PLM systems empower businesses to achieve product excellence in fast-paced markets by enhancing collaboration, agility and innovation.

Read how the Campaign Planner & Designer (CPD) helps you to manage supply chain variability.

© Camelot Management Consultants, Part of Accenture

Camelot Management Consultants is the brand name through which the member firms Camelot Management Consultants GmbH, Camelot ITLab GmbH and their local subsidiaries operate and deliver their services.