AI-Driven Application & Process Testing: Embracing Agentic Testing

Learn how Agentic AI enables digital transformation, delivering true hyperautomation.

The pharmaceutical industry is currently undergoing a digital transformation to improve its supply chain planning capabilities, leveraging new technologies. These efforts are crucial for safeguarding patient well-being amidst constantly evolving regulatory demands and supply chain disruptions. Drawing from client interactions and our understanding of ongoing supply chain challenges, we have outlined the top ten requirements that companies must address for a successful transformation. Neglecting these aspects poses a risk to the digital roadmap, potentially resulting in unsuccessful implementation and missed business benefits.

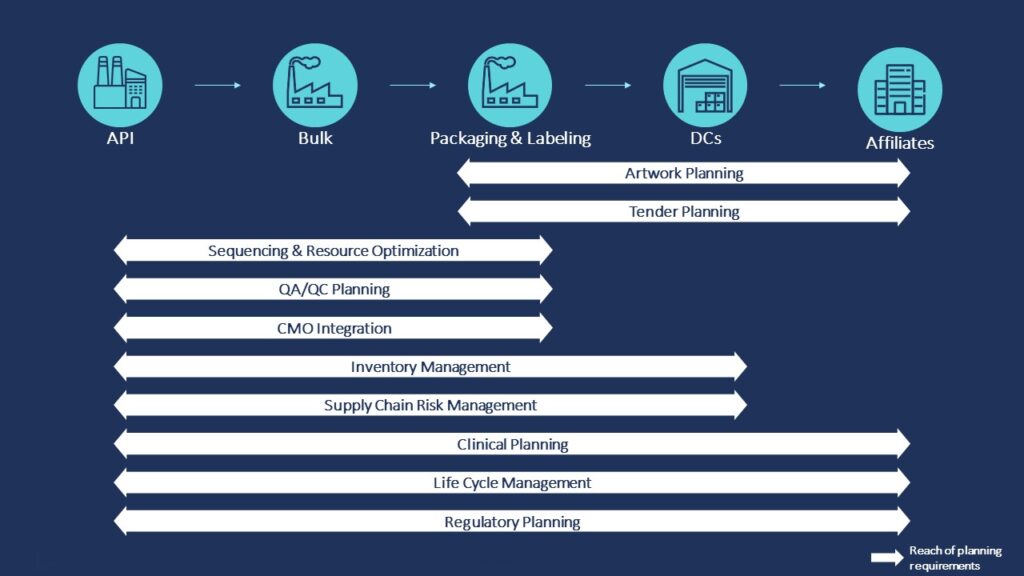

Figure 1 represents the top 10 planning requirements from Camelot’s perspective. These requirements are not listed in order of importance. Importance varies by company depending on the complexity of their supply chain and scope of implementation. However, all ten are applicable in any case.

Figure 2 maps the impact each requirement has on the supply chain. This portrays the parts of the supply chain that need to be involved, or at least considered, when defining solutions to approach these requirements. The indicated scope of the supply chain must undergo a complete transformation for the business to meet all expected benefits. The extent of the reach for each requirement will vary between companies, depending on factors like their product mix and network complexity.

With these selected requirements, our goal is not to diminish the importance of the general planning requirements, such as automated forecasting and constrained supply planning, which are vital for implementing a comprehensive end-to-end supply chain planning process. Instead, we aim for this selection to be viewed as essential components that planners should integrate when designing and implementing the end-to-end planning processes and digital solution landscape in the pharmaceutical industry. This will ensure that the digital transformation returns the expected business benefits.

Learn how Agentic AI enables digital transformation, delivering true hyperautomation.

Reimagine resilience and proactively minimize supply chain risks

This article shall help you to understand how to optimize your inventory positions in a month – or even less.

Modern PLM systems empower businesses to achieve product excellence in fast-paced markets by enhancing collaboration, agility and innovation.

© Camelot Management Consultants, Part of Accenture

Camelot Management Consultants is the brand name through which the member firms Camelot Management Consultants GmbH, Camelot ITLab GmbH and their local subsidiaries operate and deliver their services.